Our recommendations are made independently. We may receive commissions from purchases made via our links.

Material Retention for Electric Knife Sharpeners

We check the amount of material removed after an electric knife sharpener brings a dull knife to sharpness level 9.

This test is part of How We Test and Rate Electric Knife Sharpeners v1.0

Because it directly affects the lifespan of your knives, material retention is always among the top criteria when we test and pick the best knife sharpeners.

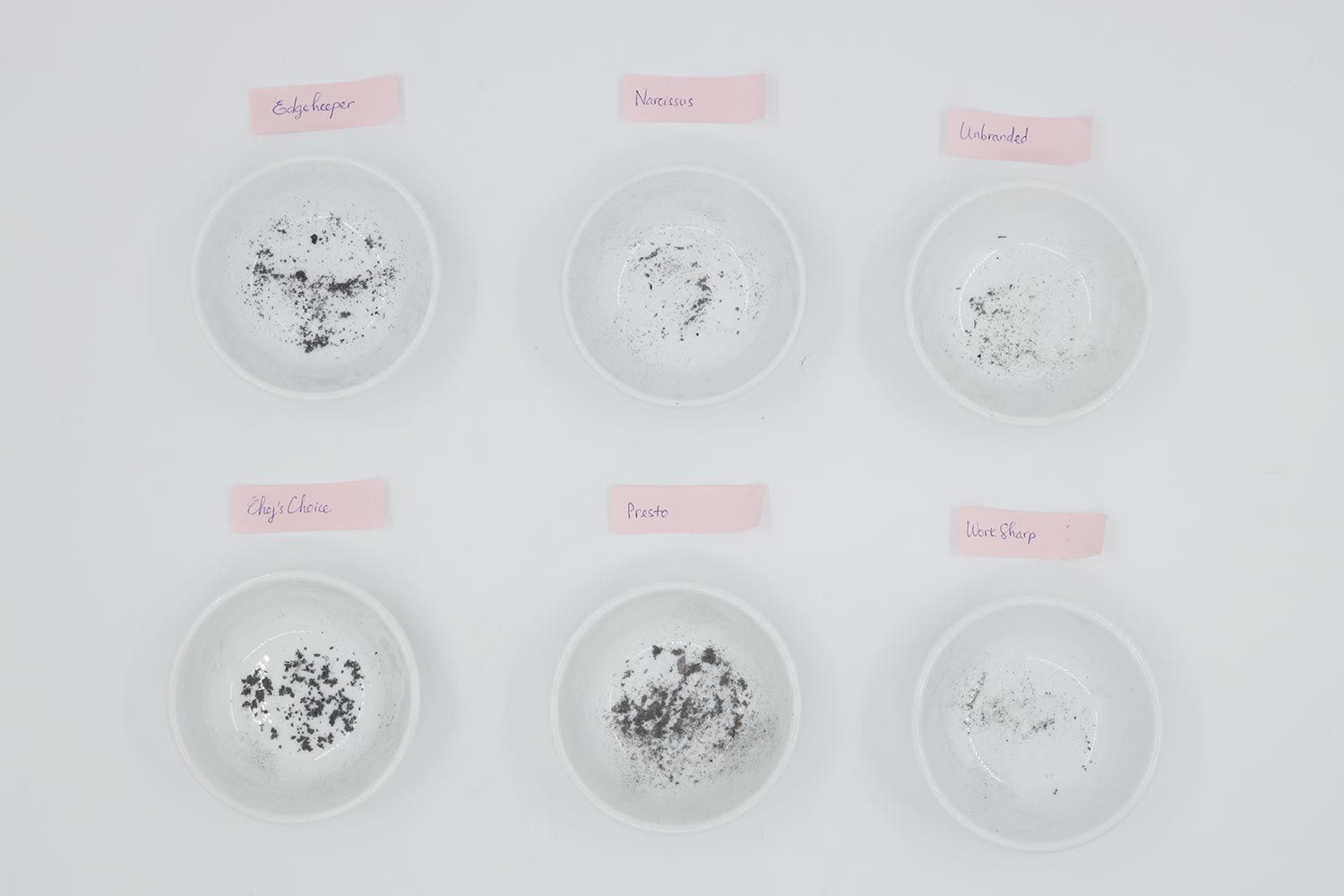

Electric sharpeners, with their powerful motors and fast-turning abrasive wheels, get a bad rap for removing too much material from the knife edge. After testing out a bunch of machines, we found that the amount varies dramatically from one sharpener to the next. Using a set of identical test knives, we set out to determine how much material each sharpener removed and which factors (grind angle, abrasive material, abrasive coarseness, and speed) affected it most.

For this evaluation, we collect the material residue after sharpening a test knife on each electric sharpener. Then, we rate the sharpeners according to the amount of residue.

Why Material Retention Matters

The removal of steel is inevitable when you want to restore a keen edge to a dull knife. However, if a lot of material is removed every time you sharpen your knife, it won’t be long before the blade changes character. The shallower blade will throw off its balance and make certain tasks harder.

The effect is especially obvious on a knife with a fingerguard or bolster that extends all the way to the heel where the abrasive wheels on an electric sharpener cannot reach. This not only looks unsightly, it also affects the knife’s shape and thus its agility on the cutting board. The thinned blade with a heel that sticks out can prevent it from performing certain motions or tasks, such as rocking or slicing thin ingredients.

On the other side of the coin, the sharpener loses some of its own material every time it grinds against a steel blade, too. The more material lost, the less effective the abrasives become. As a result, you will have to spend more time sharpening to achieve the same result.

For all those reasons, we want an electric knife sharpener that loses and removes only the minimal amount of material necessary to produce a sharp edge.

Material retention makes up 10% of the total Performance score.

How We Test Electric Knife Sharpeners for Material Retention

Let’s talk about how we assess a sharpener’s ability to save knife material while sharpening.

Equipment

- Electric sharpener

- 8-inch, 20-degree-bevel, stainless steel chef’s knife

- Screwdrivers to disassemble the sharpener

- Small brush and bowl to sweep and collect metal dust

- Clock app to record the sharpening time

- Camera with magnifying lens and prop for holding the knife.

The Test Procedure

The collection and inspection of residue are carried out after the Speed test where we sharpen a blunt knife to the point that it can cut beef tendon.

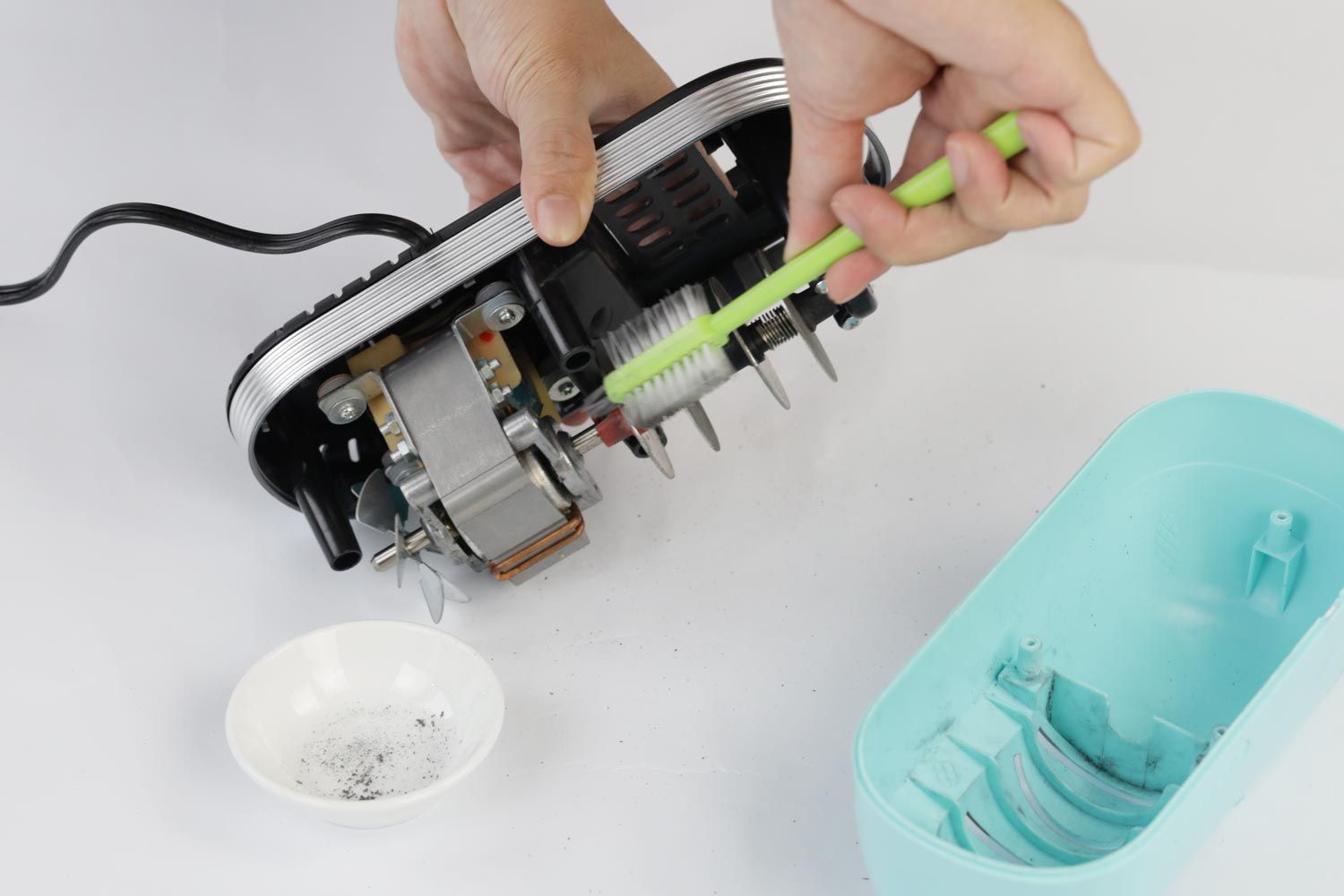

Step 1. Immediately after the Speed test is completed, we use a fine brush to collect the metal particles on the outside of the machine as well as the dust on the table’s surface.

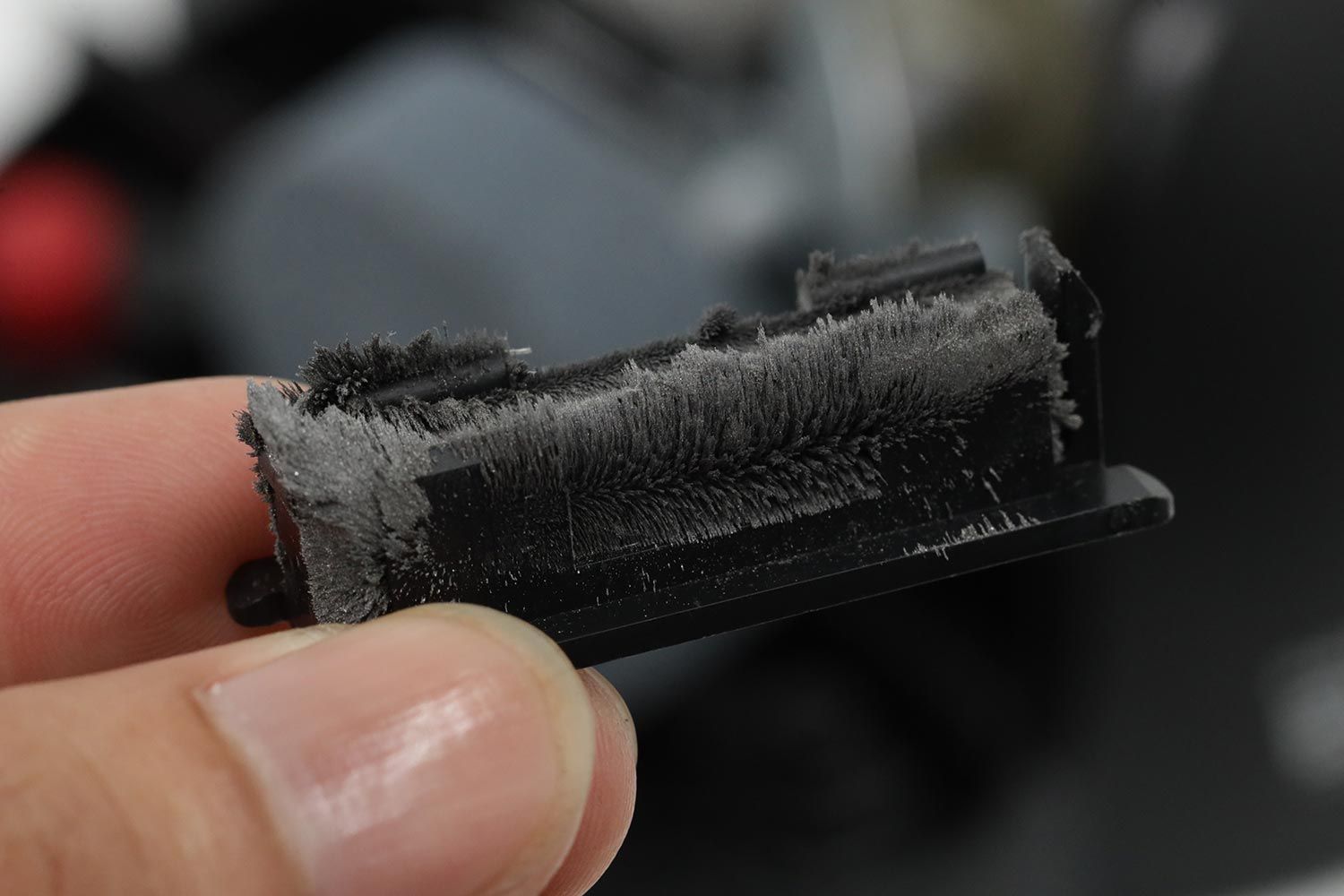

Step 2. We disassemble the machine and brush out any metal residue trapped inside, especially that which accumulates on the magnetic plate under the abrasive wheels.

All the dust and residue are collected in a small white bowl for inspection.

How We Rate Material Retention

Some electric sharpeners lose and remove only a negligible amount of material, which makes weighing a challenge. Instead of basing the score on weight, we compare the amounts of residue and give 10 points to the machine producing the smallest amount, 1 point to the one producing the greatest amount of residue, and rank those that fall in between accordingly.