Our recommendations are made independently. We may receive commissions from purchases made via our links.

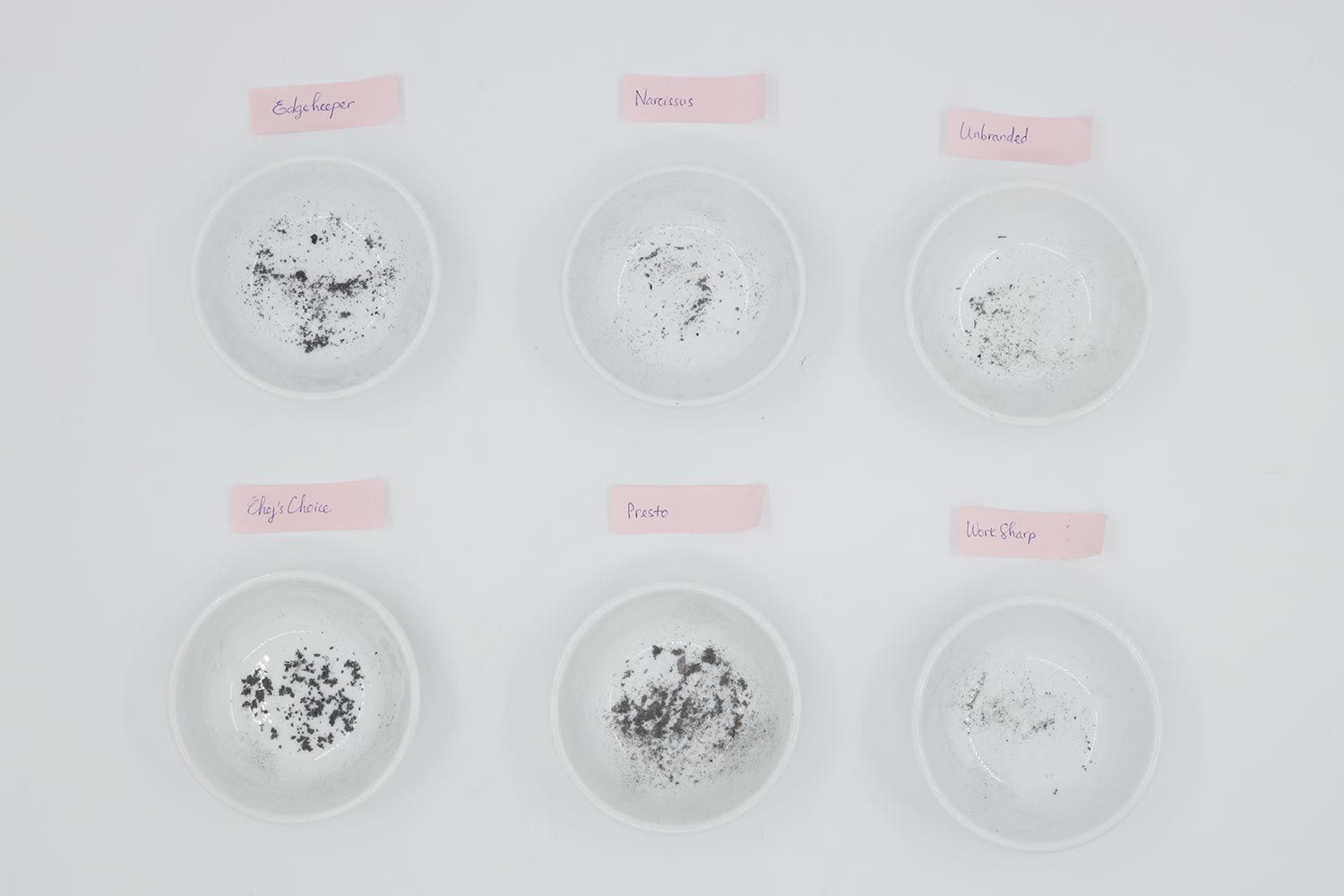

Edge Quality for Electric Knife Sharpeners

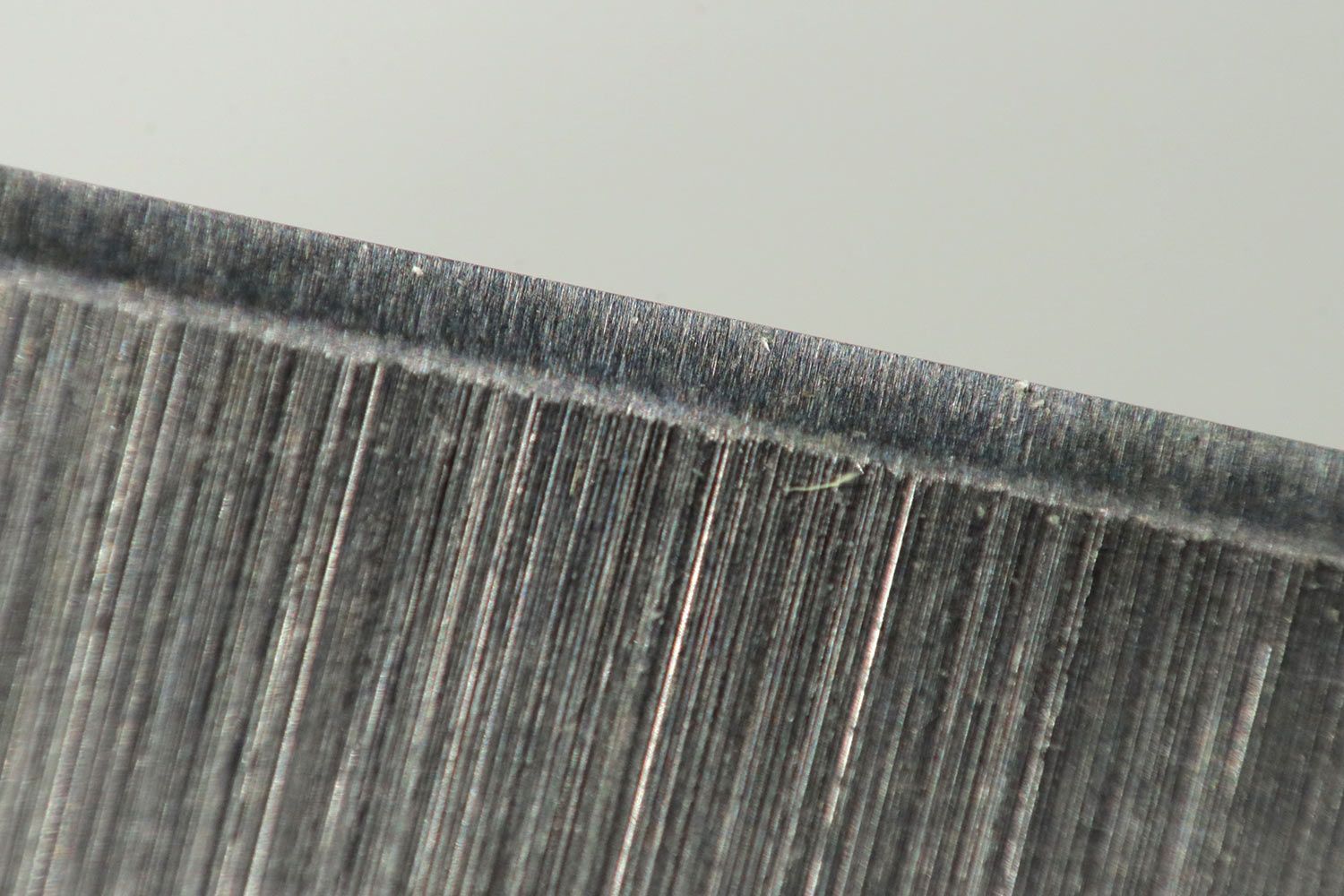

We check the knife edge for smoothness, evenness, and width after running it through the electric sharpener.

This test is part of How We Test and Rate Electric Knife Sharpeners v1.0

With most electric sharpeners, an effective edge is guaranteed. The quality of the knife edge after sharpening, however, can be vastly different from one machine to another. Edge quality depends largely on the sharpener’s stability, grind angle, and abrasives. It matters what they’re made of and how coarse or fine they are.

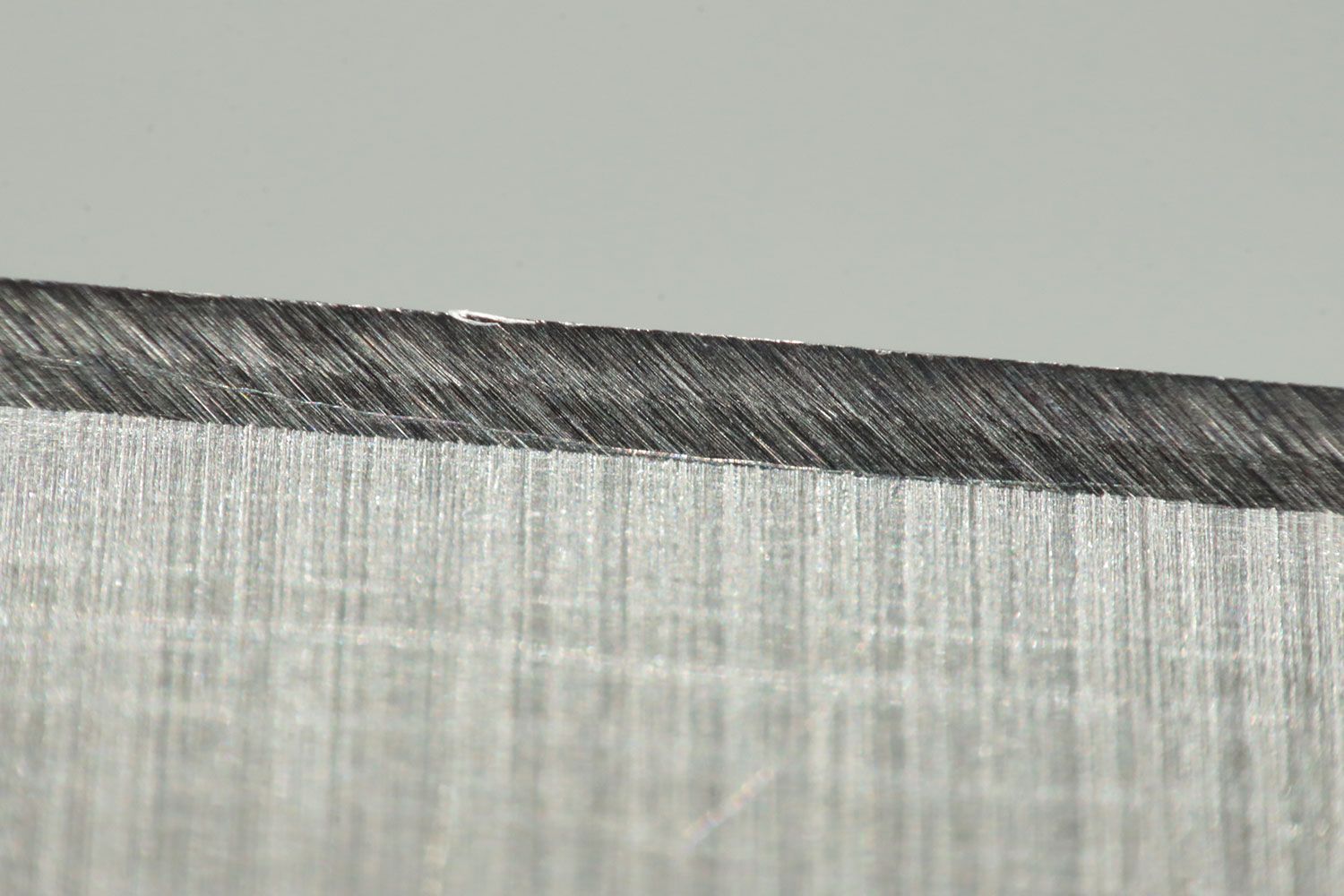

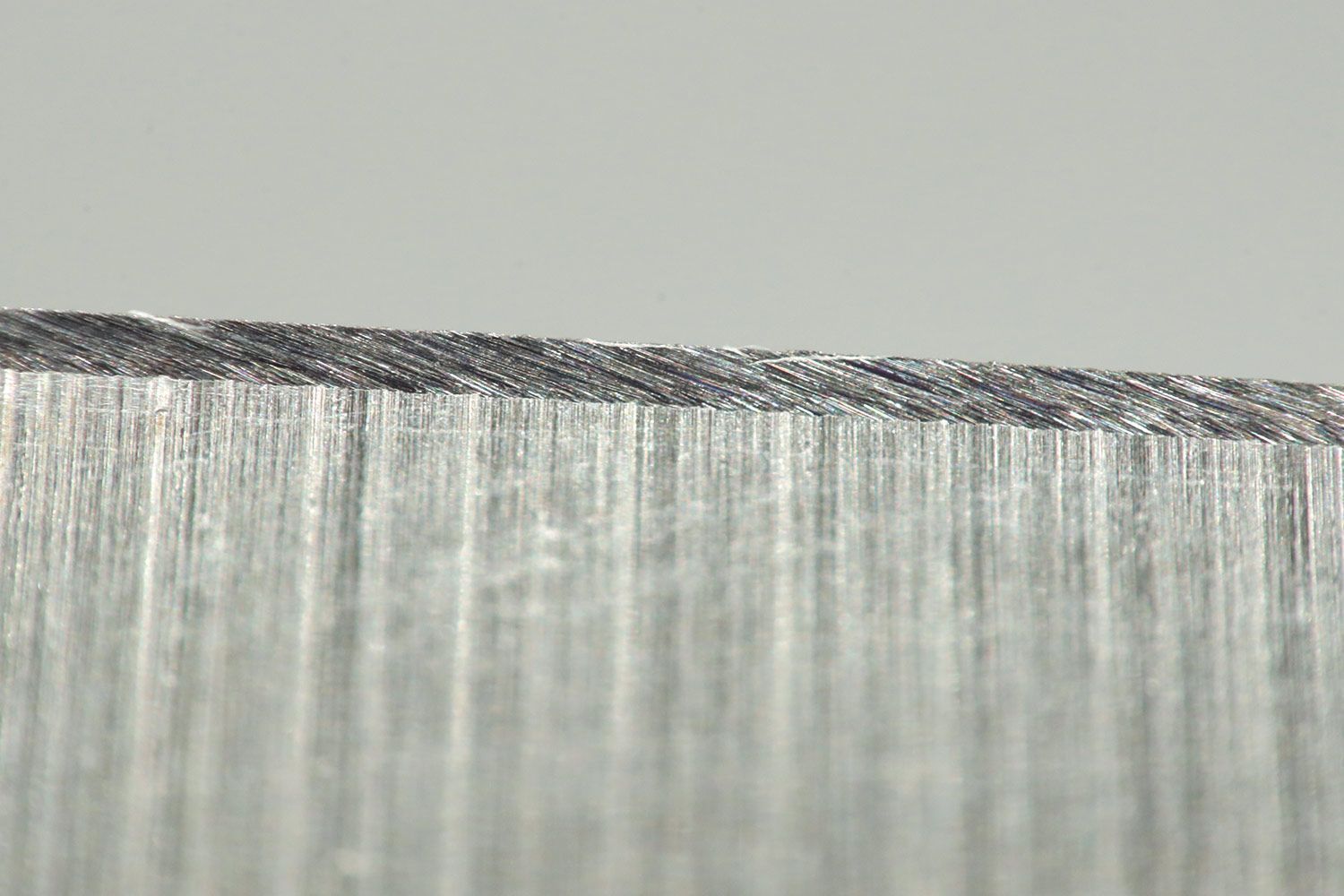

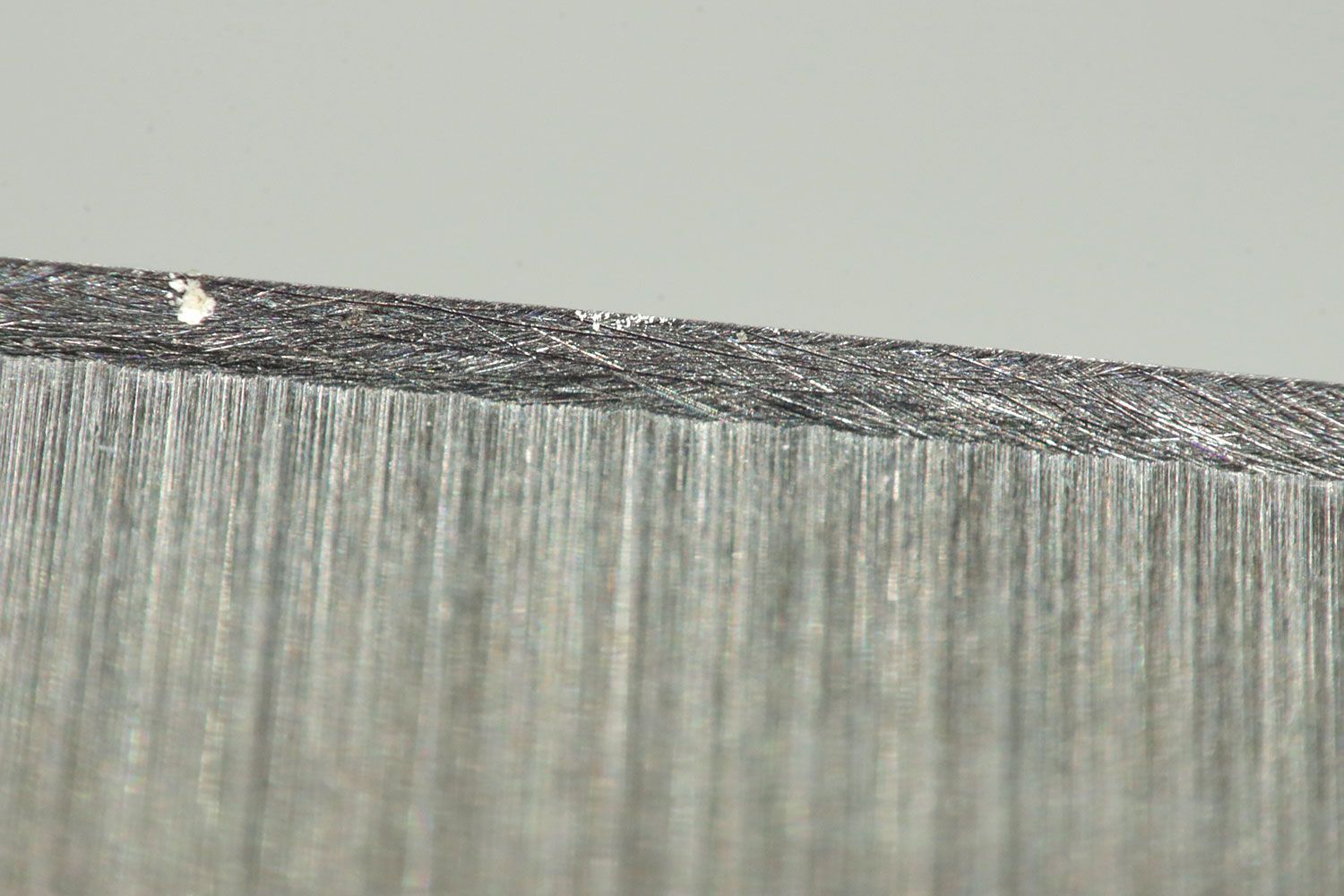

In this test, we inspect and rate the knife edge for its height, finish, and the evenness of the bevels after sharpening with an electric sharpener.

Why Edge Quality Matters

You want knife sharpeners that can produce a high-quality edge because such can cut more easily and stay sharp longer, thus saving you maintenance time.

The actual smoothness of the edge is a matter of preference. Most pros, though, like a smooth and straight edge not only because it’s pleasant to look at, but for the smoother and cleaner cuts it creates. Likewise, while uneven bevels have their uses, good evenness makes for straighter cuts.

Edge height, meanwhile, has been proven to affect sharpness and edge retention. For a given blade thickness, the edge with a greater height has a more acute edge angle, which allows it to slice more easily through dense material. Interestingly, it also remains sharp longer.

Edge finish, height, and bevel evenness respectively make up 50%, 30%, and 20% of our total Edge Quality score, which in turn constitutes 40% of the Performance score for electric knife sharpeners.

How We Test Electric Knife Sharpeners for Edge Quality

This test is conducted immediately after the Speed Test.

Equipment

Here’s a list of what we use to assess the knife edge quality.

- Electric sharpener

- 8-inch, 20-degree-bevel, stainless steel chef’s knife

- Clock app to record the time

- Camera with magnifying lens and prop for holding the knife.

The Test Procedure

We inspect the knife edge on both sides after sharpening it to level 9 and note the approximate height and evenness of the edge.

Next, we take a magnified photograph of the edge so we can inspect its finish more closely. We then discuss and decide on the rating for each category.

How We Rate Edge Quality

We rate each of the sharpeners for edge finish, height, and bevel evenness separately on a scale of 1 to 10. A score of 1 means the edge has a poor, rough finish, a low height, or uneven bevels. A score of 10 means the knife edge is good in each of those categories.

Then we calculate the final edge quality score using the following formula:

Edge quality rating = Finish score x 50% + Height x 30% + Bevel evenness x 20%