Our recommendations are made independently. We may receive commissions from purchases made via our links.

How We Test and Grade Portable Bullet Ice Makers v1.0

Portable countertop ice makers produce versatile bullet-shaped ice. You simply fill the water tank and press start. But, how much ice do they make and what else do you need to know? Learn more about how we independently test and grade ice makers before you decide to buy one.

Portable ice makers are convenient for their bullet-shaped ice, usually made in small or large sizes. This ice is suitable for most types of drinks and also ice beds for beverages or seafood.

With over 7,400 minutes or 120 hours of ice making, we help you understand how to get the best out of any bullet ice maker you buy. Find out how we test portable countertop ice makers, how we rate them, and what we have learnt from hours of continual ice making.

Our Overall Testing and Evaluation Procedure

- Performance (60%)

- Usability (25%)

- Design (15%)

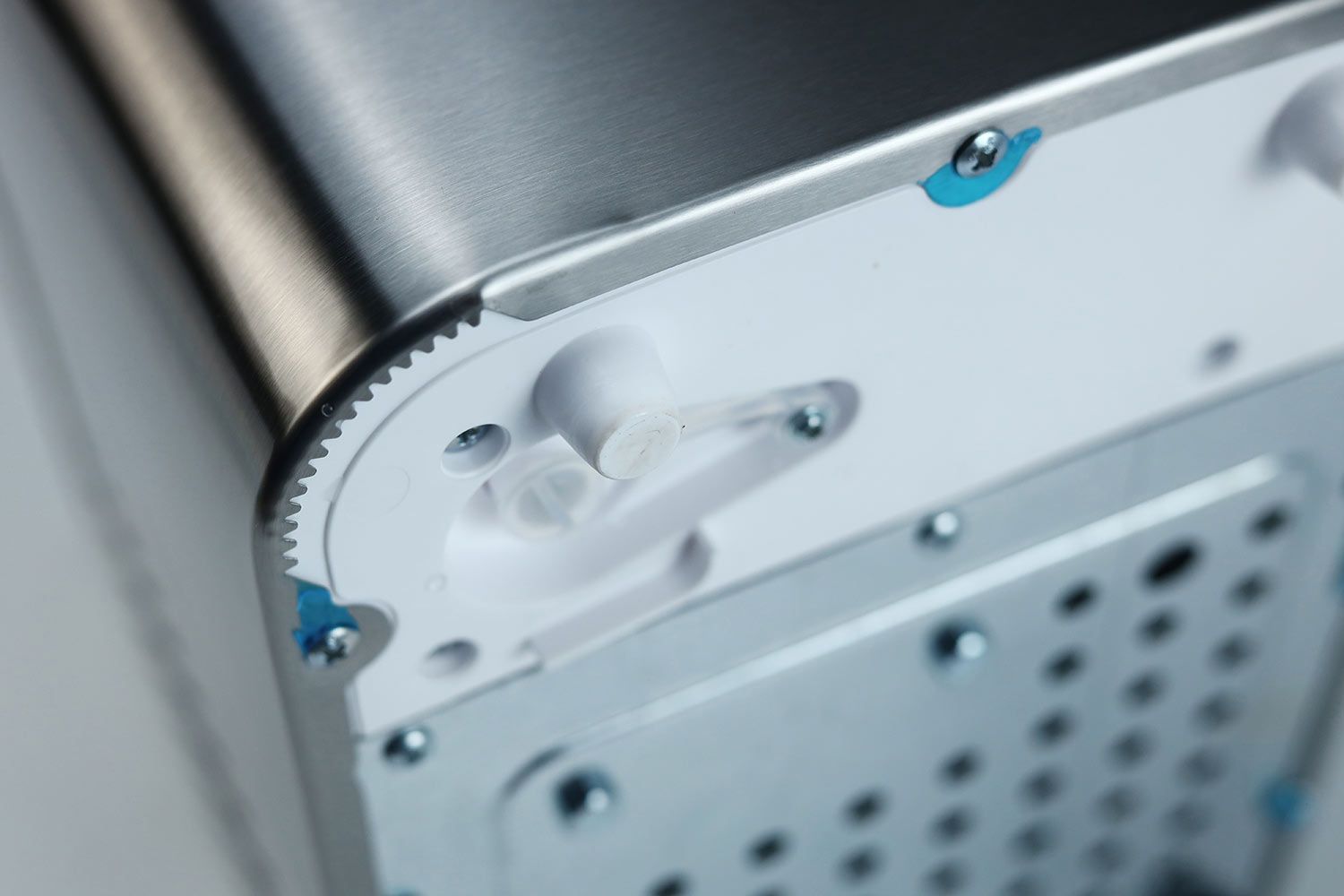

In order to score and grade portable bullet ice makers, we put each machine through an identical set of tests and grading procedures. We purchase all machines at our own expense and, after unboxing, we photograph each machine in detail.

Before we start testing, we research test methods and run sets of preliminary tests. Then, the testing team finalizes which tests to run and how to score the machines. Tests run with two to four members of our testing team present and all tests are continuously recorded on video.

We conduct the following data tests on all machines:

- Ice Capacity Test - 60% of Performance Score

- Ice Quality Test - 40% of Performance Score

- Noise Test - 25% of Usability Score

In addition to these scientific data-based tests, we assess the machines for usability, or how intuitive it is to use each machine, and if upkeep and maintenance is straightforward. We also grade machines for design features and build quality.

Performance Score Tests

In our weighted scoring system, Performance counts for 60% of the total score. Of performance, the Ice Capacity Test accounts for 60% while the Ice Quality Test is 40% of the performance score. These tests are carefully designed by our testing team and also video recorded as an additional control measure.

Usability Score Assessment

Through hours of repeated testing and practical everyday use, we also gauge how easy and intuitive the machines are to use. For our usability assessment, we score three categories on a scale of 1 to 10, each differentially weighted:

- Noise - 25%

- Ease of Use - 60%

- Cleaning - 15%

Only the Noise (25%) test is a data driven test. We simply measure decimal levels in an enclosed room with machines producing large-sized ice bullets. This is scored against a benchmark of 60 dB. Most machines advertise a noise level of 40 dB which tends to be small ice bullet making in unstated ideal conditions. For large ice bullets, we add 20 dB and most machines tend to operate between 67 and 69 dB.

Usability also includes an Ease of Use (60%) evaluation which is scored 1 to 10 points on a descriptive scale and further subdivided into three sections:

1. Controls: Each machine control panel is assessed for its ease of use in terms of positioning, visibility, and responsiveness (5 pts).

2. Visibility: We assess visibility in how easy it is to see the ice rods or the interior of the machine (3pts). The latter is important in case of an ice malfunction and also for detecting any calcification on the ice rods.

3. Scoop Leverage: We assess how easily and quickly you can scoop ice out the basket. Factors which affect this are relative basket size, basket shape and design, as well as material quality (2pts). The basket as such is scored under Design.

Cleaning (15%) is scored on a descriptive scale of 1 to 10 points. We first note how easy it is to clean the external body, especially finger prints (3pts). Then, we assess internal cleaning which involves the tank, the water guard, and the rice rods (4pts). Lastly, we score the drainage plug for material quality and how easily the tank drains (2pts). We add a point to machines that have self-cleaning.

Design Score Assessment

For the design score, each machine is graded on a descriptive scale for the following:

- Build Quality - 45%

- Lid Design - 25%

- Panel Design - 15%

- Ice Basket - 15%

Build quality (45%) relates to the perceived quality of the external materials as well as fit and finish of parts and joinings. For each 1 point discrepancy between the initial build quality score and performance score we subtract 1 point from the build quality score. We do this because some machines, while good on the outside, lack expert mechanical design.

10 | Excellent quality + original design |

|---|---|

9.5 | Excellent fit and finish all parts |

9 | Good quality with minor exception |

8 | Average to good quality |

7 | Below expectations |

6 | Less than acceptable |

Lid design (25%) is scored for its material quality (3pts), joinings (2pts), visibility (3pts) and tested insulation or the ability to maintain ice quality over an 8-hour period (2pts). In the ice capacity performance test we prep the machines by running them overnight and noting the comparative degree of ice degradation the following morning. This gives a real indication of the design quality as it relates to good insulation.

Panel design (15%) is graded for the size and design of the buttons (3), material quality (3), and design features which includes placement, effectiveness of a raised or flat design, and use of icons (4pts).

Ice basket (15%) is likewise graded for its material quality (3pts), the fit in its hold (3pts), the size (3pts), and we add a point for special features like a raised edge . Sometimes a poorly designed ice basket can interfere with the infrared sensor that triggers the Ice Full alert.