Our recommendations are made independently. We may receive commissions from purchases made via our links.

Scrap Mix Test for Garbage Disposals

Let’s see how well garbage disposals can grind down a mixture of random scraps from stringy veggies to tough animal bones compared to one another.

This test is part of How We Test Garbage Disposals v1.1

The point of an in-sink garbage disposal is to swallow everything, grind it up so it won’t clog the plumbing, and leave behind nothing. In this particular test, we aim to answer one question: how well do these disposals handle a mixed range of food scraps?

Why Scrap Mix Matters

From the moment of their invention, garbage disposals have always faced off against big loads of waste material that threaten to clog the works.

Pushing food down the drain is problematic, to say the least, without a good disposal system. They help pulverize leftovers before any of them hit the pipes and significantly reduce the risk of blockage. At least, that is what we are told.

In this particular test, we aim to showcase what comes out of a food disposer after it swallows significant amounts of kitchen scraps in order to put each model’s performance into perspective.

The evidence we collect, categorize, and document by going under the sink, and into the grind chambers, helps bring light to normally covert issues. A clear example of said issues is how some of the fish bones are able to slide through certain models nearly intact.

Additionally, the test highlights capacity issues behind these disposals, especially in the case of weaker models. In our early tests, the volume of input materials had a drastic impact on the outcome. A little trial and error helped the team drill down to the apparent limits and we updated our methods accordingly.

Test Procedure

1. Preparation

To conduct the test, we first have to prepare some equipment and the appropriate mix of scraps. Some of the important items are hard to find, but it’s all worth the effort in the end. We also partner with local businesses to use their avocado scraps as well as thrown-away corn cobs and eggshells so we don’t have to waste much food.

Something else to note here is that the fish and chicken bones in this particular test are all cooked. We save the raw stuff for other tests.

List of equipment:

- Scale

- Scraps tray

- Timer

- Sound level meter

- Rubber cleaning gloves

- Running water

- Drain baffle

- Garbage disposal

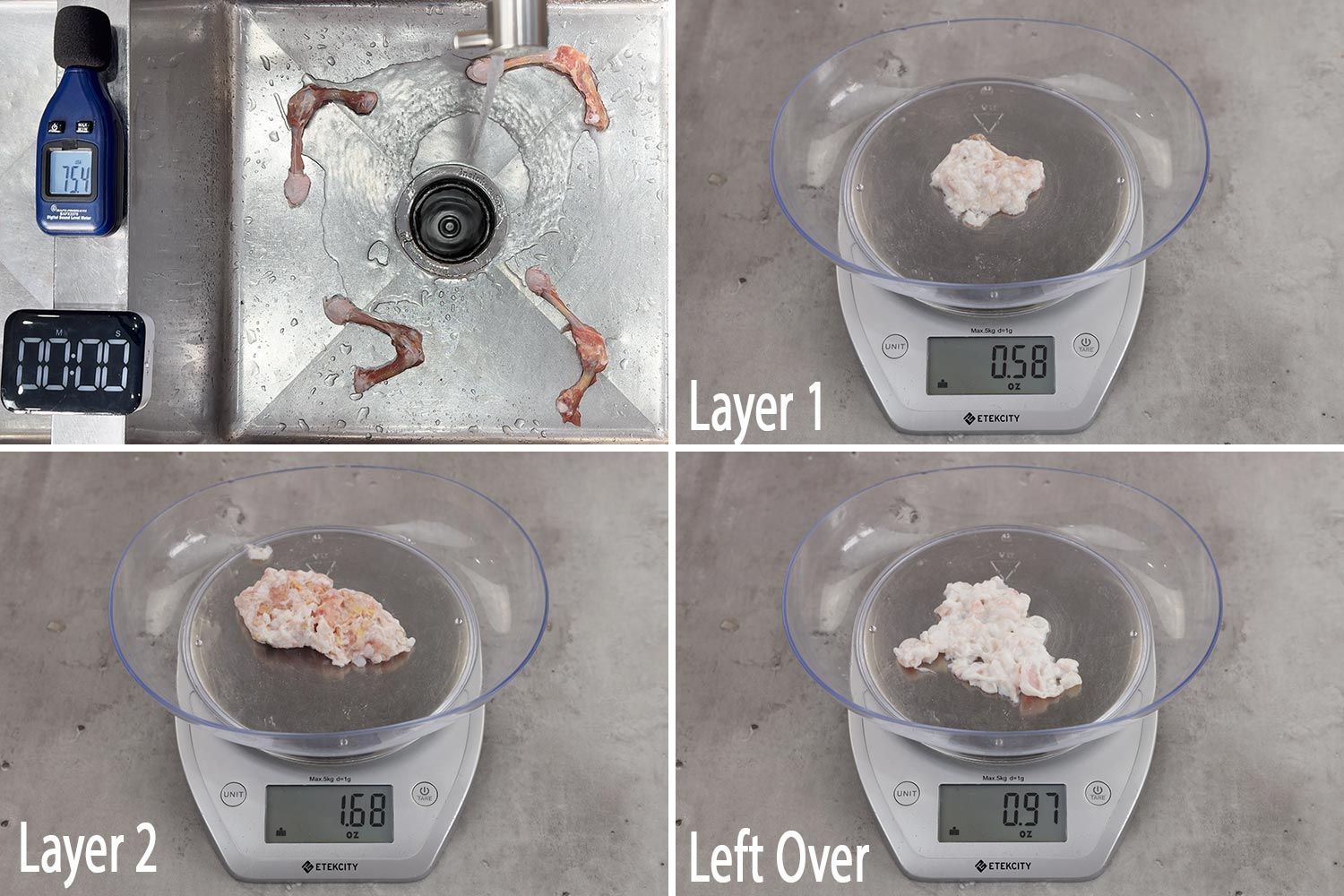

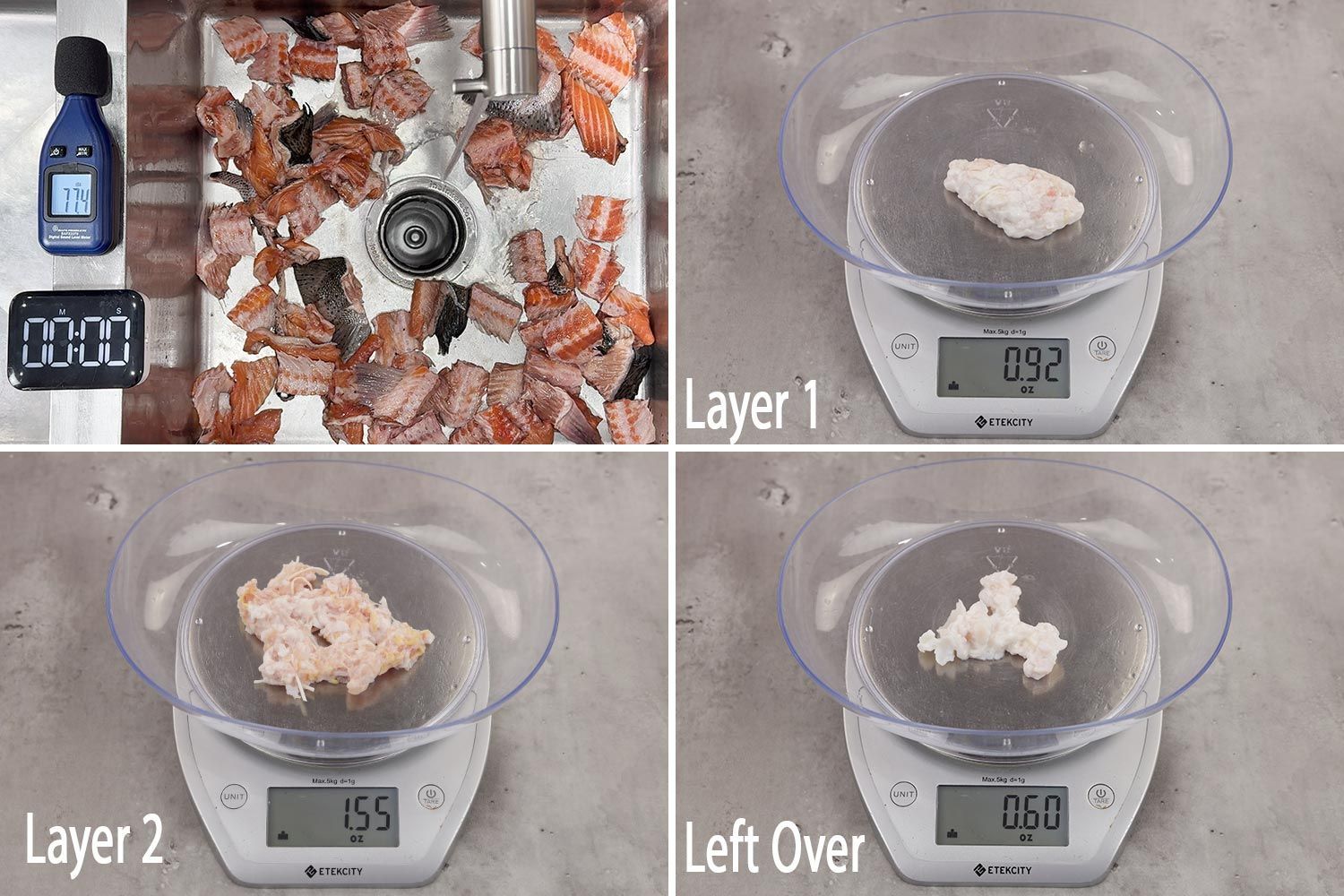

- (Layer 1) Shallow 18½-inch plastic colander with round holes (~ 0.08 sq in)

- (Layer 2) Deep 18½-inch plastic colander with rounded square holes (~ 0.05 sq in)

- Deep 20-inch water container

We stack the shallow and deep colanders to create a two-layer screening device, with Layer 1 on top catching large pieces and Layer 2 below catching smaller pieces. The two layers with different openings help us categorize the output into two groups which we will measure in step 3 of the test.

List of Ingredients:

Total weight: ~ 90 oz (2535-2590 g)*

- Eggshells: ~ 1.4 oz (35-40 g)

- Apples slices: ~ 8.8 oz (245-250 g)

- Squeezed oranges: ~ 10.5 oz (295-300 g)

- Lemons: ~ 10.5 oz (295-300 g)

- Potatoes: ~ 12.3 oz (345-350 g)

- Celery: ~ 8.9 oz (250-255 g)

- Avocado pits: ~ 2.8 oz (75-80 g)

- Avocado peels: ~ 2.8 oz (75-80 g)

- Corn cobs: ~ 5.2 oz (145-150 g)

- Cooked chicken bones: ~ 3.1 oz (85-90 g)

- Cooked fish bones: ~ 24.6 oz (690-700 g)

*The figures shown are for one run.

Having calculated an agreeable value range, we weigh everything, from the eggshells to the fish bones. We next add them up to a final sum so we can conveniently compare different loads later on. The intention is to make sure that all candidates receive their fair share of work and minimize the margin of error.

2. Execution

- Step 1: With the drain baffle in position, we throw the prepared scraps in the sink and mix them up the best we can. We also break up some of the big chunks of fish bones during this stage. Next, we remove the baffle(1) when possible, place the screener in position and move on to the next step.

- Step 2: We put on running water, turn on the machine, start the timer and the noise level meter, and proceed to flush stuff down. Each candidate will operate for no longer than 4 minutes or until the majority of the input load has been processed(2) with the materials going in continuously.

- Step 3: After turning the machine off, we collect the scraps that have accumulated on each layer of our device, dry everything, and weigh each category of materials respectively. Then, we gather all remaining scraps, i.e. the leftovers inside the grinding chamber, and weigh that as well. We call these leftovers Layer 3.

(1) Removing the baffle makes it easier to herd scraps down the drain.

(2) When we can’t remove the baffle to visually judge the progress, we listen to the noise.

Note: We avoid forcing food down the drain when possible. The disposal should be doing the work, after all. We only intervene if scraps appear stuck. We pause when a disposal jams to unjam its motor or when a disposal overheats to wait for the circuit breaker to reset, then continue the test until the time is up or the candidate has overheated 3 times.

3. Scoring

The test focuses on how efficient the selected garbage disposals are at grinding down garbage, with everything traveling through the drain pipes with the lowest risk of clogging. One effective way to predict such clogs is by evaluating the size of scraps that every machine outputs.

Based on the amounts of leftovers, processing times, and weights of Layer 1 (large pieces) and Layer 2 (small pieces), we begin scoring the products.

We set the Pass/Fail criteria as follows:

- If a candidate has overheated three times, the run fails.

- If the leftovers are more than 1% of input load after 4 minutes, the run fails.

The input load is decidedly fixed at 90 ounces, so if a candidate leaves behind less than 0.9 ounces, it will pass.

Time, in turn, is scored as follows:

- A candidate scores a 10 if it finishes (less than 0.9 ounces of leftovers) under 2 minutes.

- For every 30 seconds beyond, a candidate loses 1 point.

Because herding the mix down the drain already takes 1 minute 15 seconds or so, with the average time across all runs also considered, we feel that 2 minutes is the appropriate time mark to start scoring.

Next, Layer 1 and 2 are scored:

- If Layer 1 catches less than 3% of the input load, it receives 10 points. For every 4% beyond, it loses 1 point.

- If Layer 2 catches less than 5% of the input load, it receives 10 points. For every 4%, it loses 1 point.

In other words, because the amount of Layer 1 (large pieces) is more critical in causing/avoiding clogging, we take points from it at a more critical threshold than Layer 2 (small pieces). A model gets a perfect score if, in under 2 minutes, less than 2.7 ounces of release are caught by the first colander and no more than 4.5 ounces are caught by the second. The chunkier the output, the less effective the garbage disposal.

A product’s final rating for the Scrap Mix Test takes the scoring of Time, Layer 1, and Layer 2 into account: Time takes 25%, Layer 1 takes 40%, and Layer 2 takes 35%, with Layer 1 claiming the majority for its heavier impact on the drains.

Examples

Let’s take a look at some of the results we collected:

Insinkerator Evolution Excel: 9.8 points

Finishing time is at 1 minute 58 seconds, receiving 10 points. The final rating of 9.7 draws 40% from Layer 1, which is 4 points, and 35% from Layer 2, which is 3.3 points, and 25% from Time, which is 2.5 points.

GE Disposall Green Disposer: 7.8 points.

Finishing time is at 2 minutes 13 seconds, receiving 9.6 points. The final rating of 7.8 draws 40% from Layer 1, which is 2.9 points, and 35% from Layer 2, which is 2.5 points, and 25% from Time, which is 2.4 points.